We protect businesses across the Gold Coast, Brisbane, and Northern NSW with thermal imaging.

Think Thermal Imaging offers comprehensive commercial thermal imaging solutions to protect your business from costly breakdowns, inefficiencies, and fire risks. Our thermal imaging scans provide precise, non-invasive inspections of electrical systems, mechanical equipment, and building structures, identifying potential problems before they escalate.

With over 25 years of experience in the electrical industry, our thermographers are all Infraspection Institute Certified Level 3 and fully licensed electricians, ensuring you receive the highest quality service.

What is a Thermal Imaging Scan?

A thermal imaging inspection uses infrared technology to detect heat emitted from objects and equipment not visible to the human eye. By visualising temperature variations, our scans can identify overheating components, insulation issues, and hidden water leaks that would otherwise go unnoticed. This non-contact method allows for safe, fast, and comprehensive inspections, reducing the risk of damage or downtime.

What Can a Thermal Imaging Scan Detect?

Thermal imaging is a powerful tool that can detect various issues in your commercial & industrial premises:

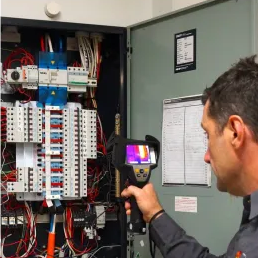

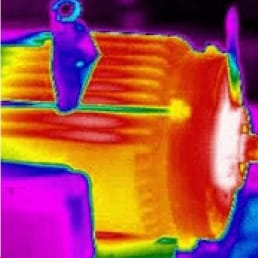

Overheating and circuit overload in electrical and mechanical systems: A thermal scan identifies hotspots in electrical switchboards and wiring, allowing for timely maintenance and the prevention of electrical fires.

Energy inefficiencies: Our equipment can detect heat loss through poor insulation, air leaks in HVAC systems, and unsealed windows or doors. A thermal imaging report pinpoints where energy savings can be made.

Water leaks: Thermal imaging can spot moisture hidden behind walls or under floors, preventing structural damage and mould growth.

Pests: Scans can identify rodents and other pests hiding in concealed areas.

Structural defects: Flaws in construction and insulation can be detected early, preventing future costly repairs.

What Happens During a Thermal Imaging Survey?

During a commercial thermal inspection, our thermographer uses advanced thermal cameras to scan your electrical switchboards, mechanical equipment, and building infrastructure. The scan is quick, non-invasive, and provides real-time data.

Afterward, you’ll receive a comprehensive thermal imaging report detailing any issues that have been identified.

Why Choose Think Thermal Imaging for Your Business?

Prevent costly breakdowns: Early detection of issues helps prevent unexpected equipment failure, reducing downtime and expensive repairs.

Increase safety: Thermal imaging for electrical systems identifies potential fire risks, ensuring your electrical infrastructure operates safely.

Improve energy efficiency: A thermal scan highlights areas of energy loss, allowing you to implement solutions that reduce energy costs and improve compliance with building codes.

Insurance compliance and lower premiums: Many insurance companies now require thermal imaging reports as part of their risk assessments. Regular inspections can lead to reduced premiums.

Why Do Insurance Companies Require Thermal Imaging?

Many insurance companies include thermal scanning as a requirement for commercial fire risk assessments, using electrical thermography to identify potential risks before they escalate into major incidents like fires or explosions.

These inspections help assess electrical problems in commercial properties, reducing the risk of fire and protecting both businesses and insurers from significant losses. By implementing a maintenance programme, you can comply with insurance requirements, detect and address small issues early, and potentially lower your premiums.

Check your insurance policy for more details. Depending on your insurer, thermal imaging may help reduce commercial insurance premiums

Areas We Service

Think Thermal Imaging proudly serves businesses across the Gold Coast, Northern NSW, and Brisbane regions. From industrial plants to office buildings, we help protect a wide range of commercial and industrial properties with our comprehensive thermal imaging services. Click here for a full list of suburbs we service.

Who We Service

We specialise in providing commercial thermal inspections for various industries, including:

- Manufacturing facilities

- Commercial office buildings

- Industrial plants

- Hospitality venues

- Shopping centres

- Warehouses and storage units

Certified

All Think Thermal Imaging thermographers are Infraspection Institute Certified Level 3.

Experience

All Think Thermal Imaging thermographers are highly skilled electricians with over 25 years experienced.

Family Owned

We are local Gold Coast electricians, a family business, owned and operated by Ben Williams, who has over 25 years experience in the electrical industry.

Insurance Compliance

Think Thermal Imaging can Implement a “Predictive Maintenance Programme” which can lower the risk of catastrophic failure and therefore, lower insurance costs.

Fully Licensed

We’re a fully licensed and insured business. We operate locally and comply with the Safety Management System. You can rest assured knowing that all our work comes with a high quality guarantee.

High-Quality

We provide exceptional customer service that creates loyal customers for life and are willing to refer our business to their family, and colleagues. Our genuine passion for delighting and helping our customers are one of the many reasons why we continue to operate and even expands our workforce.

LET’S BOOK A FREE CONSULTATION

For reliable thermal imaging for electrical systems, energy audits, and predictive maintenance, trust Think Thermal Imaging. Get in touch today to book your thermal imaging scan and protect your business from costly downtime and repairs.

Electrical Systems

Insurance Compliance

Mechanical Systems